Calibrating that first layer is essential, and he provides handy instructions to dial it in. There’s extensive guidance on getting the bed adhesion just right, as you can’t have it come off mid-print, but you need it to detach cleanly and easily when the arm sweeps across the bed. We were especially impressed with the attention to detail in the documentation for this one. The slicer needs to change as provides some G-code to reset the printer and clear the print.

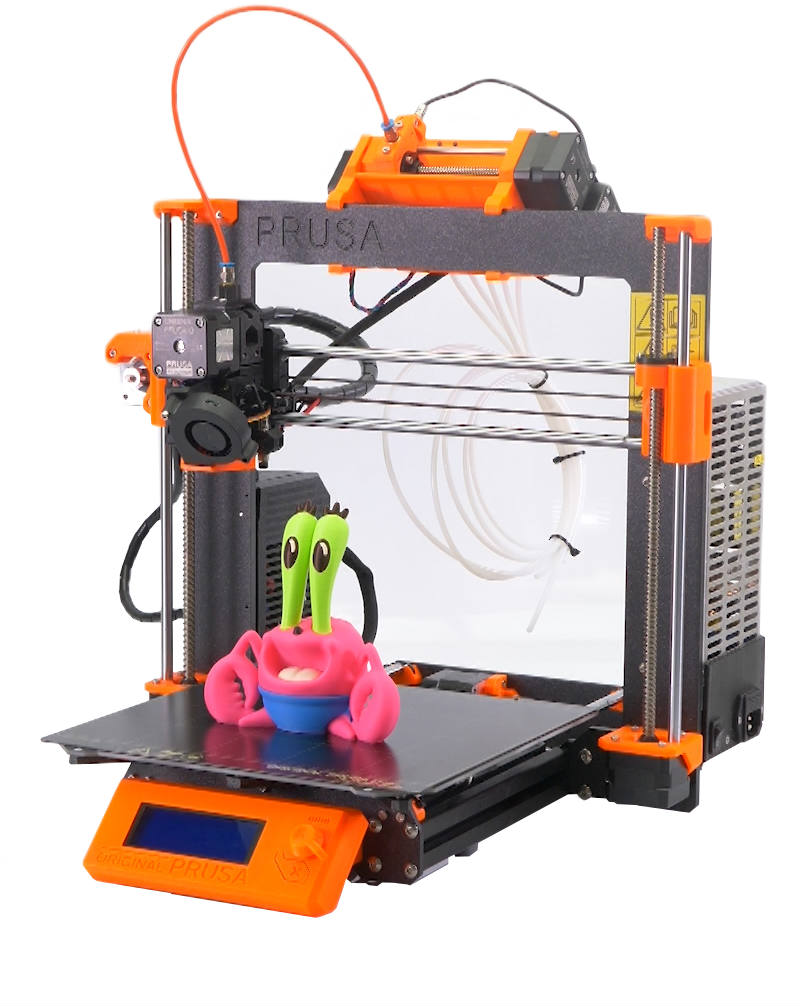

The next step is to modify OctoPrint to allow a continuous print queue. First, there’s an arm that sweeps the build plate to clear the printed pieces, a slide for the pieces to descend on, and a stand for the printer to sit on that puts it at an angle. The setup was dubbed Loop and consisted of a few parts. Not, as he decided that his Prusa i3 MK3S+ would print continuously. What if you needed to print 600 little parts for whatever reason? Most people might say get lots of printers and queue them up. One of the issues with 3D printing is that when a print is done, you need to go back and pull the print off the bed to reset it for the next one. He’s running OctoPrint on a Raspberry Pi, though as we’ve covered recently, a small form factor desktop computer could just as easily run the show.Ĭontinue reading “Custom Prusa MK3 Fan Duct Gives Camera Perfect View” → Posted in 3d Printer hacks Tagged borescope, nozzle camera, Octoprint, prusa, Prusa i3 Mk3 But judging by the sharp and bright demo video he’s provided, we’d say the extra effort was certainly worth it.Īfter covering how the camera rig was put together, then goes over how it was integrated into OctoPrint, including how the external LEDs are switched on and off. While modifying the printed parts took some effort, he says the hardest part of the whole build was salvaging a 5X lens from a handheld magnifier and filing it down so it would fit neatly over the camera. The camera module included a few tiny SMD LEDs around the lens, but added holes to the fan duct to fit a pair of 3 mm white LEDs to really light things up. Since the duct blows right on the printer’s nozzle, it provides an ideal vantage point. The first step was to find a community-developed fan duct, which he then modified to hold the 7 mm camera module. recently decided to outfit his Prusa i3 MK3S+ with such a camera, and was kind enough to share the process in a write-up. Some argue that this perspective can provide valuable insight if you’re trying to fine tune your machine, but whether or not there’s a practical application for these sort of nozzle cams, certainly everyone can agree it makes for a pretty cool video. A growing trend is to mount a borescope “inspection camera” near a 3D printer’s nozzle to provide a unique up-close view of the action.

0 kommentar(er)

0 kommentar(er)